Teknoloji’nin sağladığı tüm imkanları kullanarak, müşterilerimizin ihtiyaçlarını da göz önünde bulundurarak, sürdürülebilir gıda ambalajı çözümlerini sunmak.

Teknoloji’nin sağladığı tüm imkanları kullanarak, müşterilerimizin ihtiyaçlarını da göz önünde bulundurarak, sürdürülebilir gıda ambalajı çözümlerini sunmak.

Yerel ve küresel gıda üreticilerinin ambalaj ihtiyaçlarına; değer katan, yenilik ve farkındalık yaratan ambalaj ürünleri sunarak, tercih edilen küresel gıda ambalaj üreticisi olmak.

Müşteri Odaklılık: Hizmet ve ürün kalitemizi ön planda tutarak müşterilerimizi dinler, anlar ve onların memnuniyetini sürekli üst seviyede tutarız.

Verimlilik: Tüm faaliyetlerimizde finansal ve operasyonel verimliliği gözetecek şekilde hareket ederiz.

Yeniliğe ve Öğrenmeye Açıklık: Kendi pazarımızdaki tüm yeniliklere açık olarak çalışır, bu yeniliklerin uygulanmasında sektörümüze öncülük ederiz.

Güvenilirlik: Tüm müşteri , tedarikçilerimiz ve iş ortaklarımızla karşılıklı güven bilincini aşılayacak şekilde çalışır, bu güvenin kaybolmamasına özen gösteririz.

Çevre ve Toplum Bilinci: Bu bilinci, iş sürecimizin merkezine yerleştirerek, yeni nesillere sağlıklı ve mutlu bir dünya bırakmak için çalışıyoruz.

Katılımcı Yönetim: Çalışanlarımızın fikirlerini önemser, şirketin gelişimine katkıda bulunmaları için onların bilgi ve yetkinliklerini artırarak, sorumluluk almalarını destekleriz.

TULİPACK, 2013 yılında Thin-Wall & IML olarak adlandırılan kalıp içi etiketleme tekniği ile ince cidarlı plastik gıda ambalajı üretmek üzere faaliyete geçti. TULİPACK, yenilikçi ve teknolojik çözümleri kullanarak ürettiği ürünler ile ambalaj pazarına yeni bir bakış açısı kazandırmıştır.

2014 yılında sektördeki büyümesini sürdüren TULİPACK, hem mevcut kapasitesini artırdı hem de margarin, dondurma, süt ürünleri, dondurulmuş gıda, catering, şekerleme ve çikolata başta olmak üzere geniş bir ürün yelpazesine sahip oldu. Yine 2014 yılında TULİPACK, yurt içindeki geniş müşteri portföyünün yanı sıra yurt dışında ki müşterilere de ulaşmayı başarıp, ihracat faaliyetlerine başladı.

2015 yılında da yatırımlarına devam eden TULİPACK, Çerkezköy’deki 6.000m²’lik kapalı alana sahip, 200 milyon adet kase ve kapak üretebilecek kapasitede, son teknolojiye sahip ekipmanlarla donatılmış yeni fabrikasına taşındı. Her geçen gün artan kapasitesine paralel olarak, yurt içi ve yurt dışındaki müşteri portföyünü genişletmekte olan TULİPACK, bunu yaparken de yenilikçi, çevre dostu ve teknolojik çözümlerine de yenilerini eklemektedir.

2016 yılında 6.000m² üretim ve depolama alanına sahip, Anadolu’daki ilk fabrikasını kuran TULİPACK; Ege, İç Anadolu ve Akdeniz bölgelerindeki gıda üreticilerinin de kase ve kapak ambalajı ihtiyaçlarını karşılamaya başladı. Bu yatırım ile birlikte toplamda 12.000m² kapalı alanda 250 milyon adet kase ve kapak üretebilecek kapasiteye ulaşmış bulunuyor.

Kurulduğu ilk günden bu yana, müşteri memnuniyeti ve kalitesini ön planda tutan TULİPACK, bunun bir sonucu olarak sektördeki en önemli sertifikalar olan ISO 9001:2015, ISO 14001:2015, ISO 18001:2007, BRC-IoP, Sedex ile belgelendirilmiştir.

Kişisel verilerin işlenmesinde başta özel hayatın gizliliği olmak üzere kişilerin temel hak ve özgürlüklerini korumak ve kişisel verileri işleyen gerçek ve tüzel kişilerin yükümlülükleri ile uyacakları usul ve esaslarına önem veriyoruz.

ISO 9001-2015, BRC-IOP (AA Sınıfı) ile belgelendirilmiştir. Bu da, müşterilerimize yüksek ürün güvenilirliği, kalite ve hijyen standartlarını sağlamaktadır.

Taahhüdümüzün bir bölümü olarak, Tulipack üretimin her aşamasında titiz bir kalite kontrol çalışması uygulamaya koyarak güvenilir ürünler sunmaktadır. Yenilikçi tasarım, kullanıcı dostu ve estetik görünüm, uyumun önünde yer almaktadır.

Bu düşünceden yola çıkarak, hammaddeden bitmiş ürünlere kadar tüm süreç izlenmekte ve titizlikle kontrol edilmekte, aynı zamanda ürünlerimizin görüntü, boy ve çeşitli fonksiyonları istatiksel metodlarla kontrol edilmektedir.

Taahhütlerimizin diğer bir bölümü olarak işlerimizin her sürecinde güvenliğe ve hijyene önem veriyoruz. Gelişmiş kamera kontrol ve tam otomatik kolileme sistemi bize, ürünün her pozisyonda ve açıda kapları ve kapaklarını etiketleme şansı verir.

Kalite konusu işimizin ana unsurudur ve hepimizin günlük iş tanımında belirtilir. Hak ettiğimiz sertifikalar yüksek kalite standartlarına ulaştığımızı ve müşterilerimizin gelişmiş ihtiyaçlarını karşılayabileceğimizi garanti etmektedirler.

Tulipack Ambalaj TSE'den güvenli üretim belgesi aldı.

Tulipack Ambalaj, Türk Standartları Enstitüsü'nün (TSE) belirlediği, hijyen, enfeksiyon önleme ve kontrol değerlendirme programı şartlarını yerine getirerek 'COVID-19 Güvenli Üretim Belgesi'ni almaya hak kazandı.

Tulipack, tüm çalışma alanlarında ve üretim süreçlerinde sürdürebilirlik odaklı hareket ederek yaşam alanlarında sağlık ve hijyenden ödün vermeyen, Pandeminin ilk gününden itibaren tüm paydaşları ile küresel salgına karşı olan mücadelesini tescil ettirmenin haklı gururunu yaşamaktadır.

URSA Sosyal Sorumluluk denetimlerine katılmaktayız.

Tulipack Ambalaj olarak faaliyet gösterdiğimiz Thin Wall, IML etiketli plastik gıda ambalajı üretimi sektöründe standartlara ve yasal düzenlemelere uygun ürün üreterek, müşterilerimize sağlıklı ve güvenilir ürünler sunmak temel görevimizdir.

Ürün kalitesi ve güvenliği ile ilgili girdilerin spesifikasyonlara uygunluğunu sağlamak, tedarik, üretim, depolama ve sevkiyat aşamaları dahil tüm süreçlerde fiziksel, kimyasal ve mikrobiyolojik riskleri önlemek ve kontrol altında tutmak,

Ürün güvenliğinin sağlanmasına dair gelişen ve değişen müşteri istekleri, yasal gereklilikler ve firma hedefleri doğrultusunda sistematik düzenlemeler yapmak,

Teknolojik yeniliklerden, uygun alt yapı ve çalışma ortamında ürün güvenliğini arttıracak yönde yararlanmak,

Güvenilir ürün sağlamak için iletişim ve eğitimle çalışanlarımızın bilinçli katılımını sağlamak,

İnsan sağlığı göz önünde tutularak kurulan sistemin uygunluğunu, gelişmesini ve sürekliliğini sağlamak amacıyla prosedür ve talimatları uygulamaktır.

Her zaman temiz-sağlıklı ve güvenli ürünleri; bilgi ve tecrübelerimizi kullanarak, tüm kaynaklarımızı seferber ederek, fiziksel, kimyasal ve mikrobiyolojik kirlilik yönünden bulaşma olmamış gıdaları, müşterilerimize garanti etmek.

Önemli bir sağlık problemi olan personeli sağlık kurumuna göndermek, gerek görüldüğü takdirde iyileşinceye kadar üretim alanlarına sokmamak.

Üretim alanlarına önlüksüz, galoşsuz ve bonesiz girilmesine izin vermemek, önlükleri temiz ve boneleri saçları ve kulağı tamamen kapatacak şekilde kullanmak. Üretim alanında çalışırken alyans dahil hiçbir takı kullanmamak, makyajlı olmamak.

Üretim alanları içerisinde sigara içmemek ve yemek yememek. Uyarı levhaları asmak suretiyle ziyaretçilerin de bu kurala uymalarını sağlamak. Sadece belirlenen bölgelerde sigara içmek ve yemek yemek. Üretim alanında ceplerde sigara paketi, çakmak, kibrit ve yiyecek maddesi taşımamak.

Herhangi bir yaralanma durumunda yaranın büyüklüğüne göre sağlık kuruluşuna sevk veya gerekli görülürse mavi renkli ve metal indikatörlü yara bandının bölüm sorumlusu kontrolü altında personel tarafından kullanılmasını sağlamak ve işletme çıkışında bölüm sorumlusuna gösterilerek mevcudiyeti onaylatılmak.

Üretim alanına cam, porselen eşya sokmamak ve işletme camlarını filmle kaplı kullanmak. Kırılgan plastiklerin ve gerekiyorsa camların (Bilgisayar ekranı vs) periyodik kontrolle kullanılmasını sağlamak. Üretim ortamında ahşap materyal kullanmamak.

Kesici alet kullanma zorunluluğu olan personel için bıçağı kırılmayan, tek parça, tehlike seviyesi düşük bıçaklar temin ederek numaralandırarak personele teslim etmek. Kullanılan bıçakları kontrol ederek hasarlı bıçakların değişimini sağlamak. Personellere oryantasyon eğitimi sırasında, üretim alanında kesici alet kullanılması konusunda uyarıcı bilgiler vermek.

Tulipack Thin Wall/IML gıda ambalaj pazarı için aşağıdaki teknolojileri ve uzmanlık alanlarını sunuyor.

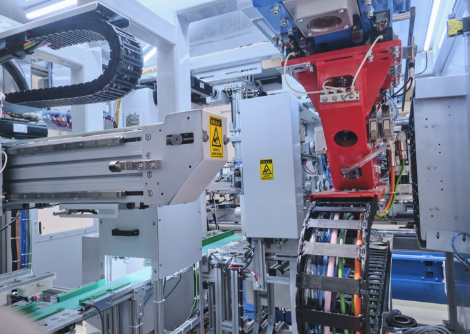

Yüksek süratli enjeksiyon kalıplama makineleri, robotik sistemler, kamera kontrolü, sandviç kalıplar bizim TW/IML uygulamaları konusundaki başarılarımızda kritik noktalardır. Tulipack’ın, kalıp imalatçıları, robot ve etiket üreticileri ile teknolojilerinin sürdürülebilirliği konusunda çalışmaları vardır. Bu, daha az ağırlık, daha az malzeme kullanımı ve daha düşük çevre tahribatı anlamına geliyor ki, bu da tüketicilerin günlük yaşantısında kolaylık getirecektir.

Tulipack teknolojiyi benimseyerek müşterilerine, piyasada farklılaşma gücü veren ürün çözümleri sunmaktadır. Bunu başarabilmek için de müşteriler ile yakın temasta çalışıp, tecrübe ve becerilerini kanıtlanmış teknolojileri de kullanarak isteğe bağlı çözümler geliştirmektedir.

Tulipack Ambalaj A.Ş. ve çalışanları olarak, ulusal ve uluslararası yasal mevzuat ve düzenlemelere uyar, sürekli gelişmeyi temel alan bir İş Sağlığı ve Güvenliği Yönetim Sistemi dâhilinde sağlıklı ve güvenli bir çalışma ortamı yaratırız.

Hiçbir iş kazası engellenemez veya kabul edilebilir olarak addedilmemelidir. Hedefimiz; uygulanabilir, tutarlı ve güncel yasal mevzuatlara uygun iş sağlığı ve güvenliği önlemlerini ortaya koyarak, kazasız bir işyeri yaratmaktır. Bu hedefimizi gerçekleştirmek amacına yönelik; karşılıklı bilgi ve deneyim aktarımı, herkesin görüşlerinin ve önerilerinin alınması ile katılımlarının sağlanması bu konuda başarının anahtarı olacaktır.

Faaliyetlerimizi Kalite ve Çevre Yönetim Sistemleri ile birlikte bütünleşik bir şekilde yöneterek, Thin Wall Plastik Enjeksiyon sektöründe iş sağlığı ve güvenliği açısından öncülüğümüzle örnek bir kuruluş olmak için tüm gücümüzle çalışırız.

TULİPACK, iş sağlığı ve güvenliğini ön planda tutma konusundaki kararlılığını bu alandaki çalışmalarını yoğunlaştırarak sürdürecek, bu amaçla kurmuş olduğu sistemini sürekli iyileştirecek ve geliştirecektir.